Adequate aeration is critical to proper canola storage

October 24, 2025

By Trevor Bacque

The “set it and forget it” mantra may work for a slow cooker, but not freshly harvested canola. When it comes to storage of what is likely your most expensive crop to produce and usually your most lucrative to sell, a multifaceted approach to storage is a must.

Lorne Grieger is an agricultural engineer and director of technical sales at the Prairie Agricultural Machinery Institute (PAMI) based in Humboldt, SK, and has more than 20 years experience studying grain storage and associated technology. He says your canola can sit in the bin long-term undisturbed if needed, but it takes good preparation on your part.

Air: your invisible ally

So much of successful canola storage centres around one critical factor: airflow. “Make sure that whatever setup you’re using for storage, it has a capability to maintain a desired airflow rate based on the condition of the seed going into the bin at the time of harvest,” says Grieger.

Start with the fact that canola needs to be under 10 per cent moisture for safe long-term storage. At that percentage, the industry standard for airflow in a bin of canola is 0.1 cubic feet per minute (CFM) per bushel for proper aeration. However, if you need to dry your canola down, the guidance is 1.0 CFM per bushel.

A big issue farmers contend with is the seed size of canola — it’s the smallest of all major crops, which causes additional airflow resistance. The ability to maintain adequate airflow can mean the difference between actually drying grain and simply cooling it. Your fan type — whether axial, centrifugal or in-line — its size and the general resistance to airflow it has to push against, will determine the optimal airflow requirement from that fan.

Resistance to airflow is called static pressure and the type of fan you have will determine how it handles said pressure. For instance, axial fans have low airflow but usually only handle high static pressure, while a high-speed centrifugal fan has high airflow but only works on low static pressure. Keep in mind that, as horsepower increases, fans generally generate higher airflows at a higher static pressure.

“If you have too much grain in the bin for your fan and it exceeds the capacity of your fan, the fan is turning, but you’re not putting air through that grain mass, that’s the risk that goes with it,” says Grieger. “That’s where you must understand what your fan is capable of relative to what you have in your bin.”

Check your manufacturer’s fan curve information sheet for the best way to measure airflow relative to the static pressure rating. Use an analog pressure gauge that automatically translates static pressure to airflow rates for various fan sizes and styles. “That does all that conversion for you and shows if you’re in a safe spot,” says Grieger. He adds it’s also important to know how your bin is ducted to make sure you have airflow across the entire diameter of the bin and make certain you can get airflow through the whole bin.

“Air is a tricky one because it takes the path of least resistance and yet you want to force it through the entire grain mass,” says Grieger.

Natural air

Fall is a good time to utilize Mother Nature whenever possible. Warm ambient temperatures have the capacity to dry grain, and the warmer the air the greater the quantity of moisture that it can remove, explains Grieger.

As time goes on and temperatures drop, air has less capacity to absorb moisture from the canola. “That’s where adding heat to the air will actually turn a cool fall day into a warm summer day,” he says.

Don’t forget that canola can respire in the bin. It may be dry upon entry but can respire again due to microbial respiration after about six weeks, underscoring the need for regular monitoring. Farmers should have their fans going when canola goes into the bin, even if the outside air temperature is warm, to minimize hotspots. Turn fans back on if heating is suspected. Turning the grain is another tool if a heating is suspected. Moving the grain helps reduce the risk of spoilage by breaking up any warm spots that may develop.

Monitor your investment

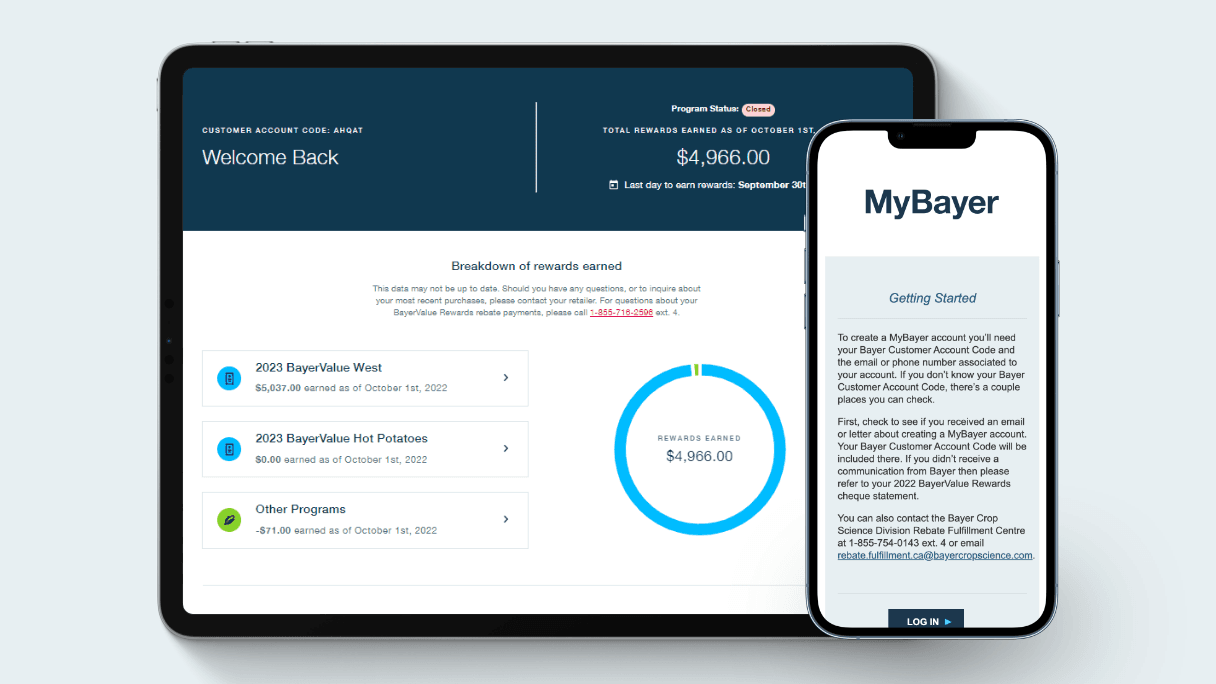

In 2025, you have wired and wireless options to monitor what’s going on in your canola bins – from plugging in a controller at the bin itself, to being able to make adjustments from your smartphone miles away from the farm.

Monitoring cables are rapidly becoming table stakes and a baseline expectation for any bin. Cable systems start around $5,000 and go up from there, which more and more farmers are seeing as a small but worthwhile investment, considering the volume of grain that can be stored in modern mega bins.

The more sophisticated, remote monitoring systems not only show you the temperature and moisture in the bin but also allow a person to turn fans on and off from afar, although changing fan speed will likely still need someone to be there in person. Advanced tech, such as GrainViz, goes so far as to generate 3D images of moisture distribution in a bin, which aims to give farmers ultimate control.

No matter how sophisticated your bin tech, you still need to pay attention to grain going in the bin and what’s already there. “If the grain coming off the field is a different condition than what’s already in the bin you want to make sure that you have air flow through it,” says Grieger, adding that farmers need to know the temperature of canola already in the bin versus what’s about to go in. “Your lower risk is always to make sure that it’s cool and it’s dry.”

Emerging tech in the future may see free floating sensors inserted through the auger and removed during screening. This has potential to generate a near limitless amount of data — everything from temperature, moisture, humidity, sound, movement, location and airflow.

Be prepared

Grieger encourages farmers to have a stock of redundant parts on hand in case any bin-related components break down during harvest — extra fans, motors, controllers and more.

As he says, you never want to be shut down over a part that could have easily been ordered months ago, and likely one you would need anyway. “You put all the effort and expense into getting the seed in the bin, so make sure that it stays safe,” he says.